Manufacturing

Services für die Industrie 4.0.

Keine Smart Factory ohne durchgängige Digitalisierung

Unsere ganzheitliche Methodik hilft Ihnen, die richtigen Lösungen zu finden und umzusetzen.

In der Idealvorstellung einer Smart Factory sind Werkstücke und Maschinen intelligent miteinander verknüpft, sodass sich Fertigungsanlagen und (innerbetriebliche) Logistiksysteme nahezu selbst organisieren. Dem Menschen kommt im Zeitalter der Digitalisierung nur noch eine überwachende und optimierende Rolle zu. Die Realität sieht in den meisten Fällen leider anders aus: Einzelne Produktionsprozesse sind mit Hilfe von Insellösungen umgesetzt, sodass es im Übergang zum nächsten Produktionsschritt zu Informationsverlusten und Fehlern aufgrund von Kommunikationsproblemen kommen kann. Von Industrie 4.0 sind die meisten Unternehmen noch weit entfernt.Die bridgingIT-Gruppe verfügt in den Bereichen Smart Factory, Master Data Management und Lean Management über die erforderliche Methoden- und Technologiekompetenz, um aus der Vielzahl von Identifikations-, Ortungs- und Kommunikationstechnologien die richtige Auswahl zu treffen.

Keine Smart Factory ohne durchgängige Digitalisierung

Unsere ganzheitliche Methodik hilft Ihnen, die richtigen Lösungen zu finden und umzusetzen.

In der Idealvorstellung einer Smart Factory sind Werkstücke und Maschinen intelligent miteinander verknüpft, sodass sich Fertigungsanlagen und (innerbetriebliche) Logistiksysteme nahezu selbst organisieren. Dem Menschen kommt im Zeitalter der Digitalisierung nur noch eine überwachende und optimierende Rolle zu. Die Realität sieht in den meisten Fällen leider anders aus: Einzelne Produktionsprozesse sind mit Hilfe von Insellösungen umgesetzt, sodass es im Übergang zum nächsten Produktionsschritt zu Informationsverlusten und Fehlern aufgrund von Kommunikationsproblemen kommen kann. Von Industrie 4.0 sind die meisten Unternehmen noch weit entfernt.Die bridgingIT-Gruppe verfügt in den Bereichen Smart Factory, Master Data Management und Lean Management über die erforderliche Methoden- und Technologiekompetenz, um aus der Vielzahl von Identifikations-, Ortungs- und Kommunikationstechnologien die richtige Auswahl zu treffen.

Keine Smart Factory ohne durchgängige Digitalisierung

Unsere ganzheitliche Methodik hilft Ihnen, die richtigen Lösungen zu finden und umzusetzen.

In der Idealvorstellung einer Smart Factory sind Werkstücke und Maschinen intelligent miteinander verknüpft, sodass sich Fertigungsanlagen und (innerbetriebliche) Logistiksysteme nahezu selbst organisieren. Dem Menschen kommt im Zeitalter der Digitalisierung nur noch eine überwachende und optimierende Rolle zu. Die Realität sieht in den meisten Fällen leider anders aus: Einzelne Produktionsprozesse sind mit Hilfe von Insellösungen umgesetzt, sodass es im Übergang zum nächsten Produktionsschritt zu Informationsverlusten und Fehlern aufgrund von Kommunikationsproblemen kommen kann. Von Industrie 4.0 sind die meisten Unternehmen noch weit entfernt.Die bridgingIT-Gruppe verfügt in den Bereichen Smart Factory, Master Data Management und Lean Management über die erforderliche Methoden- und Technologiekompetenz, um aus der Vielzahl von Identifikations-, Ortungs- und Kommunikationstechnologien die richtige Auswahl zu treffen.

Top-Themen

Ist-Situation

Viele Logistikprozesse sind heute schwer messbar. Die Ortung und Navigation von Assets und das Tracking von Bewegungen sind nur mit „Insellösungen“ realisierbar. Das erhöht den Aufwand für die Integration einer Ortungs-Infrastruktur. Hinzu kommen die typischen Verschwendungspotenziale in der Logistik: Leerfahrten, doppelte Routen, lange Wege, Suchen und Warten, Schäden durch Transport und Lagerung.

Problem

Gefühlt ist die Verschwendung im Logistikbereich sichtbar, messbar ist sie oftmals nicht. Hinzu kommen erhebliche Aufwendungen für die Implementierung von Ortungslösungen in die bestehende Business-Landschaft. Verschiedene Ortungstechnologien verwenden beispielsweise unterschiedliche Koordinatensysteme. Positionsdaten aus GPS- und WLAN-basierenden Systemen sind nicht kombinierbar. Dies macht ein nahtloses Tracking ebenso unmöglich wie die Steuerung fahrerloser Transportsysteme.

Herausforderung

Viele Unternehmen erkennen die Potenziale einer optimierten, vielleicht sogar automatisierten Materialversorgung am Band. Solche Lösungen umzusetzen gestaltet sich heute als schwierig und der ROI ist schwer darstellbar, wodurch die Realisierung gerne mal auf die lange Bank geschoben wird. Technische Hürden und fehlende Use Cases lassen die Projekte schon in der Konzeptionsphase sterben.

Unser Beitrag

bridgingIT ist federführend an der Entwicklung der omlox-gestützten Real-Time-Location-Services-Plattform beteiligt. Durch unsere Lean-Kompetenz werden im Zuge der Einführung von Routing- und Navigationslösungen zunächst Logistik-Konzepte optimiert. Als intelligente Middleware verbindet die RTLS-Plattform dann die Ortungs- und Navigationsdaten bei drastisch reduziertem Integrationsaufwand mit der vorhandenen Business-Logik. Das Ergebnis sind transparente, messbare und automatisierbare Logistikprozesse.

Ist-Situation

Durch die Entwicklungen der letzten Jahre, die mit dem Zukauf von zusätzlichen Fertigungskapazitäten, dem Erwerb neuer Unternehmensteile und der Ansammlung vielfältiger Daten und Informationen aus dem Produktionsumfeld einher gingen, sind mittlerweile heterogene Infrastrukturen, Produktionswelten und Prozesse entstanden. Sie alle sind mit zahlreichen Herausforderungen verbunden, die ein enormes Verbesserungspotenzial in sich tragen.

Problem

Die Ausstattung von Produktionshallen und die Anordnung der Maschinen/Anlagen ist oft über Jahre gewachsen und nicht mehr optimal, wenn es um Auftragsabwicklungsprozesse, Materialtransport und Flexibilität geht. Häufig sind noch Auftragsbegleitpapiere anzutreffen, die verschwinden, verschmutzen usw. Die Folgen: eine intransparente Auftragslokalisierung und ein langsamer, ineffizienter Auftragsdurchlauf aufgrund langer Warte-, Rüst-, Wege- und Suchzeiten.

Herausforderung

Prozessoptimierungen für Shopfloor, Logistik und Administration setzen voraus, dass eine aussagekräftige Analyse der Ist-Situation existiert, geeignete Verbesserungsmaßnahmen gefunden werden und ein jederzeit nachprüfbarer Plan für eine schrittweise Umsetzung existiert. Die Messung und gezielte Beseitigung der Verschwendungspotenziale im Kontext aller Begleitprozesse ist eine große Herausforderung, die im Tagesgeschäft oft nicht geleistet werden kann.

Unser Beitrag

Lean Management ist ein wesentlicher Teil unserer Kompetenz und wir ergänzen diese Fähigkeit mit unserer IT-geprägten Umsetzungsstärke. Somit entstehen nicht nur optimierte Prozesse, sondern gleichzeitig auch die damit einhergehende IT-gestützte Infrastruktur. Die Prozessoptimierung wird mit Umsetzungskompetenz gepaart, und genau diese Brücke zum Erfolg baut bridgingIT für Sie. Alles aus einer Hand.

Ist-Situation

Klarheit und Transparenz in der Produktion, die Umsetzung einer Führungskultur, kontinuierliche Verbesserungen, Informationsaustausch und strukturierte Meetings sind Bereiche des klassischen Shopfloor-Managements. Diese Meetings werden auch für Schichtübergaben und tägliche Stand-ups zu Produktionsaufträgen genutzt. Der Aufwand für die Vorbereitung dieser Abläufe ist aufgrund vielfältiger Datenquellen und verschiedener Medien (digital und analog) nicht unerheblich.

Problem

Die Vorbereitung dieser Meetings nimmt viel Zeit in Anspruch, mit dem Ergebnis, dass die visualisierten Daten oft nicht aktuell und Ableitungen daraus nicht mehr zutreffend sind. Ausgedruckte Dokumente und händisch zusammengetragene Informationen benötigen nicht selten eine Stunde und länger. Dies beschäftigt mindestens eine Person, die damit nicht an der Wertschöpfung teilnehmen kann.

Herausforderung

Beim digitalen Shopfloor-Management sind alle KPIs und Informationen aus Drittapplikationen sowie produktionsrelevante Live-Daten auf Knopfdruck verfügbar. Wichtig sind hier die Analyse der Informationsbereitstellung und die Datenaufbereitung in aussagekräftigen Dashboards. Die großen Herausforderungen sind das UI/UX-Design, das Wann?, Wo? und Wie? der Datenvisualisierung und die Frage, welche Insights in den Verbesserungsprozess münden sollen.

Unser Beitrag

Das Vorgehensmodell der bridgingIT-Gruppe für die Einführung des digitalen Shopfloor-Managements basiert auf Microsoft 365. Dabei entsteht quasi aus „Bordmitteln“ ein MVP, mit dem Sie das Thema erkunden, weiterentwickeln und Anforderungen an eine proprietäre Softwarelösung formulieren können. Das spart Kosten, bindet alle Beteiligten in das Projekt ein und sichert eine schnelle, erfolgreiche Prozessentfaltung.

Ist-Situation

Der After Sales Bereich ist heute in der produzierenden Industrie ein wesentlicher Teil der Wertschöpfung. Aktuell werden durchschnittlich 30% der gesamten Wertschöpfung durch Ersatzteillieferungen und Services erzielt, die nach dem Verkauf des Produkts stattfinden. Der Vorteil bei diesem Bereich der Wertschöpfung ist, dass die Umsätze relativ krisenfest und konstant sind. Sie sollten daher in Zukunft anteilig höher sein.

Problem

Die Erhöhung der Wertschöpfung im After Sales und die Etablierung neuer Geschäftsmodelle scheitert oft an der noch fehlenden Digitalisierung von Informationsflüssen, der DSGVO, der Weigerung der Kunden, Informationen offenzulegen, oder an einer passenden Infrastruktur. Serviceportale waren der erste Schritt in die richtige Richtung, haben allerdings die Umsätze nur selten signifikant erhöht.

Herausforderung

Wie muss eine leistungsfähige, digitale Infrastruktur aussehen, welchen Sicherheitsrichtlinien muss sie entsprechen und wie kann eine vertrauensvolle Zusammenarbeit mit dem Endkunden gewährleistet werden? Welche Abrechnungsmodelle und welche dazu passenden Online-Dienste können dazu beitragen, die Wertschöpfung im After Sales zu steigern? Wie können MVPs für Tests aussehen, um zu ersten Aussagen zu kommen?

Unser Beitrag

Aufgrund unserer Rolle als Inkubator und Accelerator für Start-ups besitzen wir ausreichende Kompetenz, um neue Geschäftsmodelle auch für den After-Sales-Bereich zu entwickeln. Hinzu kommen Kompetenzen und Umsetzungs-Know-how für IT-Infrastrukturen und IT-Architekturen, gepaart mit der Einhaltung der DSGVO. Somit liefern wir Ideen und ihre Realisierung sowie Governance, Compliance und Risk Assessment aus einer Hand.

Ist-Situation

Die Kundenanforderungen werden immer komplexer und vielschichtiger. Die Sales-Organisation steht dadurch vor einer Herausforderung: Sie muss Informationen zu diesen sich wandelnden Anforderungen schnell, fehlerfrei und eindeutig an die Konstruktion, Arbeitsvorbereitung und Produktion übergeben. Diese Informationen werden sowohl für die Angebotskalkulation und die Vorbereitung der Fertigung als auch für den gesamten PLM/PDM-Prozess benötigt.

Problem

Viele Informationen, die über die Sales-Organisation in die Unternehmen gelangen, existieren als schnelle Mitschriften auf Papier. Dies ist oft schon die erste Fehlerquelle und führt zu langwierigen Nachfragen beim Kunden und höheren Aufwänden bei der Angebotserstellung. Hinzu kommen sehr oft erhebliche Anstrengungen der Unternehmen, neue Märkte/Regionen zu erschließen, weil immer noch die klassische Vertriebsniederlassung dominiert.

Herausforderung

Wie helfe ich meinem Kunden, seine Produktanforderungen digital, eindeutig und fehlerfrei an potenzielle Lieferanten zu übergeben, um schnell ein verlässliches Angebot zu bekommen?

Im Auftragsfall müssen die vorhandenen Informationen für Auftragsdurchlauf/PLM/PDM und After Sales mitgenutzt werden können. Zudem müssen Social-Media-Plattformen und CRM für die globale Neukundengewinnung (auch ohne lokales Vertriebsbüro) verknüpft werden.

Unser Beitrag

Online-Produktkonfiguratoren, Augmented und Virtual Reality unterstützen die Optimierung der Vertriebsprozesse. Unsere diesbezügliche Beratungs- und Umsetzungskompetenz haben wir in Projekten mehrfach bewiesen. Dies gilt auch für den Bereich des Online-Marketings und der Remote-Sales-Prozesse sowie deren Anbindung an CRM-Systeme. Ziel ist es immer, ohne Medienbrüche genügend Informationen vom Markt zu erhalten und effektive Vertriebsprozesse aufzusetzen.

Top-Themen

Ist-Situation

Viele Logistikprozesse sind heute schwer messbar. Die Ortung und Navigation von Assets und das Tracking von Bewegungen sind nur mit „Insellösungen“ realisierbar. Das erhöht den Aufwand für die Integration einer Ortungs-Infrastruktur. Hinzu kommen die typischen Verschwendungspotenziale in der Logistik: Leerfahrten, doppelte Routen, lange Wege, Suchen und Warten, Schäden durch Transport und Lagerung.

Problem

Gefühlt ist die Verschwendung im Logistikbereich sichtbar, messbar ist sie oftmals nicht. Hinzu kommen erhebliche Aufwendungen für die Implementierung von Ortungslösungen in die bestehende Business-Landschaft. Verschiedene Ortungstechnologien verwenden beispielsweise unterschiedliche Koordinatensysteme. Positionsdaten aus GPS- und WLAN-basierenden Systemen sind nicht kombinierbar. Dies macht ein nahtloses Tracking ebenso unmöglich wie die Steuerung fahrerloser Transportsysteme.

Herausforderung

Viele Unternehmen erkennen die Potenziale einer optimierten, vielleicht sogar automatisierten Materialversorgung am Band. Solche Lösungen umzusetzen gestaltet sich heute als schwierig und der ROI ist schwer darstellbar, wodurch die Realisierung gerne mal auf die lange Bank geschoben wird. Technische Hürden und fehlende Use Cases lassen die Projekte schon in der Konzeptionsphase sterben.

Unser Beitrag

bridgingIT ist federführend an der Entwicklung der omlox-gestützten Real-Time-Location-Services-Plattform beteiligt. Durch unsere Lean-Kompetenz werden im Zuge der Einführung von Routing- und Navigationslösungen zunächst Logistik-Konzepte optimiert. Als intelligente Middleware verbindet die RTLS-Plattform dann die Ortungs- und Navigationsdaten bei drastisch reduziertem Integrationsaufwand mit der vorhandenen Business-Logik. Das Ergebnis sind transparente, messbare und automatisierbare Logistikprozesse.

Ist-Situation

Durch die Entwicklungen der letzten Jahre, die mit dem Zukauf von zusätzlichen Fertigungskapazitäten, dem Erwerb neuer Unternehmensteile und der Ansammlung vielfältiger Daten und Informationen aus dem Produktionsumfeld einher gingen, sind mittlerweile heterogene Infrastrukturen, Produktionswelten und Prozesse entstanden. Sie alle sind mit zahlreichen Herausforderungen verbunden, die ein enormes Verbesserungspotenzial in sich tragen.

Problem

Die Ausstattung von Produktionshallen und die Anordnung der Maschinen/Anlagen ist oft über Jahre gewachsen und nicht mehr optimal, wenn es um Auftragsabwicklungsprozesse, Materialtransport und Flexibilität geht. Häufig sind noch Auftragsbegleitpapiere anzutreffen, die verschwinden, verschmutzen usw. Die Folgen: eine intransparente Auftragslokalisierung und ein langsamer, ineffizienter Auftragsdurchlauf aufgrund langer Warte-, Rüst-, Wege- und Suchzeiten.

Herausforderung

Prozessoptimierungen für Shopfloor, Logistik und Administration setzen voraus, dass eine aussagekräftige Analyse der Ist-Situation existiert, geeignete Verbesserungsmaßnahmen gefunden werden und ein jederzeit nachprüfbarer Plan für eine schrittweise Umsetzung existiert. Die Messung und gezielte Beseitigung der Verschwendungspotenziale im Kontext aller Begleitprozesse ist eine große Herausforderung, die im Tagesgeschäft oft nicht geleistet werden kann.

Unser Beitrag

Lean Management ist ein wesentlicher Teil unserer Kompetenz und wir ergänzen diese Fähigkeit mit unserer IT-geprägten Umsetzungsstärke. Somit entstehen nicht nur optimierte Prozesse, sondern gleichzeitig auch die damit einhergehende IT-gestützte Infrastruktur. Die Prozessoptimierung wird mit Umsetzungskompetenz gepaart, und genau diese Brücke zum Erfolg baut bridgingIT für Sie. Alles aus einer Hand.

Ist-Situation

Klarheit und Transparenz in der Produktion, die Umsetzung einer Führungskultur, kontinuierliche Verbesserungen, Informationsaustausch und strukturierte Meetings sind Bereiche des klassischen Shopfloor-Managements. Diese Meetings werden auch für Schichtübergaben und tägliche Stand-ups zu Produktionsaufträgen genutzt. Der Aufwand für die Vorbereitung dieser Abläufe ist aufgrund vielfältiger Datenquellen und verschiedener Medien (digital und analog) nicht unerheblich.

Problem

Die Vorbereitung dieser Meetings nimmt viel Zeit in Anspruch, mit dem Ergebnis, dass die visualisierten Daten oft nicht aktuell und Ableitungen daraus nicht mehr zutreffend sind. Ausgedruckte Dokumente und händisch zusammengetragene Informationen benötigen nicht selten eine Stunde und länger. Dies beschäftigt mindestens eine Person, die damit nicht an der Wertschöpfung teilnehmen kann.

Herausforderung

Beim digitalen Shopfloor-Management sind alle KPIs und Informationen aus Drittapplikationen sowie produktionsrelevante Live-Daten auf Knopfdruck verfügbar. Wichtig sind hier die Analyse der Informationsbereitstellung und die Datenaufbereitung in aussagekräftigen Dashboards. Die großen Herausforderungen sind das UI/UX-Design, das Wann?, Wo? und Wie? der Datenvisualisierung und die Frage, welche Insights in den Verbesserungsprozess münden sollen.

Unser Beitrag

Das Vorgehensmodell der bridgingIT-Gruppe für die Einführung des digitalen Shopfloor-Managements basiert auf Microsoft 365. Dabei entsteht quasi aus „Bordmitteln“ ein MVP, mit dem Sie das Thema erkunden, weiterentwickeln und Anforderungen an eine proprietäre Softwarelösung formulieren können. Das spart Kosten, bindet alle Beteiligten in das Projekt ein und sichert eine schnelle, erfolgreiche Prozessentfaltung.

Ist-Situation

Der After Sales Bereich ist heute in der produzierenden Industrie ein wesentlicher Teil der Wertschöpfung. Aktuell werden durchschnittlich 30% der gesamten Wertschöpfung durch Ersatzteillieferungen und Services erzielt, die nach dem Verkauf des Produkts stattfinden. Der Vorteil bei diesem Bereich der Wertschöpfung ist, dass die Umsätze relativ krisenfest und konstant sind. Sie sollten daher in Zukunft anteilig höher sein.

Problem

Die Erhöhung der Wertschöpfung im After Sales und die Etablierung neuer Geschäftsmodelle scheitert oft an der noch fehlenden Digitalisierung von Informationsflüssen, der DSGVO, der Weigerung der Kunden, Informationen offenzulegen, oder an einer passenden Infrastruktur. Serviceportale waren der erste Schritt in die richtige Richtung, haben allerdings die Umsätze nur selten signifikant erhöht.

Herausforderung

Wie muss eine leistungsfähige, digitale Infrastruktur aussehen, welchen Sicherheitsrichtlinien muss sie entsprechen und wie kann eine vertrauensvolle Zusammenarbeit mit dem Endkunden gewährleistet werden? Welche Abrechnungsmodelle und welche dazu passenden Online-Dienste können dazu beitragen, die Wertschöpfung im After Sales zu steigern? Wie können MVPs für Tests aussehen, um zu ersten Aussagen zu kommen?

Unser Beitrag

Aufgrund unserer Rolle als Inkubator und Accelerator für Start-ups besitzen wir ausreichende Kompetenz, um neue Geschäftsmodelle auch für den After-Sales-Bereich zu entwickeln. Hinzu kommen Kompetenzen und Umsetzungs-Know-how für IT-Infrastrukturen und IT-Architekturen, gepaart mit der Einhaltung der DSGVO. Somit liefern wir Ideen und ihre Realisierung sowie Governance, Compliance und Risk Assessment aus einer Hand.

Ist-Situation

Die Kundenanforderungen werden immer komplexer und vielschichtiger. Die Sales-Organisation steht dadurch vor einer Herausforderung: Sie muss Informationen zu diesen sich wandelnden Anforderungen schnell, fehlerfrei und eindeutig an die Konstruktion, Arbeitsvorbereitung und Produktion übergeben. Diese Informationen werden sowohl für die Angebotskalkulation und die Vorbereitung der Fertigung als auch für den gesamten PLM/PDM-Prozess benötigt.

Problem

Viele Informationen, die über die Sales-Organisation in die Unternehmen gelangen, existieren als schnelle Mitschriften auf Papier. Dies ist oft schon die erste Fehlerquelle und führt zu langwierigen Nachfragen beim Kunden und höheren Aufwänden bei der Angebotserstellung. Hinzu kommen sehr oft erhebliche Anstrengungen der Unternehmen, neue Märkte/Regionen zu erschließen, weil immer noch die klassische Vertriebsniederlassung dominiert.

Herausforderung

Wie helfe ich meinem Kunden, seine Produktanforderungen digital, eindeutig und fehlerfrei an potenzielle Lieferanten zu übergeben, um schnell ein verlässliches Angebot zu bekommen?

Im Auftragsfall müssen die vorhandenen Informationen für Auftragsdurchlauf/PLM/PDM und After Sales mitgenutzt werden können. Zudem müssen Social-Media-Plattformen und CRM für die globale Neukundengewinnung (auch ohne lokales Vertriebsbüro) verknüpft werden.

Unser Beitrag

Online-Produktkonfiguratoren, Augmented und Virtual Reality unterstützen die Optimierung der Vertriebsprozesse. Unsere diesbezügliche Beratungs- und Umsetzungskompetenz haben wir in Projekten mehrfach bewiesen. Dies gilt auch für den Bereich des Online-Marketings und der Remote-Sales-Prozesse sowie deren Anbindung an CRM-Systeme. Ziel ist es immer, ohne Medienbrüche genügend Informationen vom Markt zu erhalten und effektive Vertriebsprozesse aufzusetzen.

Top-Themen

Ist-Situation

Viele Logistikprozesse sind heute schwer messbar. Die Ortung und Navigation von Assets und das Tracking von Bewegungen sind nur mit „Insellösungen“ realisierbar. Das erhöht den Aufwand für die Integration einer Ortungs-Infrastruktur. Hinzu kommen die typischen Verschwendungspotenziale in der Logistik: Leerfahrten, doppelte Routen, lange Wege, Suchen und Warten, Schäden durch Transport und Lagerung.

Problem

Gefühlt ist die Verschwendung im Logistikbereich sichtbar, messbar ist sie oftmals nicht. Hinzu kommen erhebliche Aufwendungen für die Implementierung von Ortungslösungen in die bestehende Business-Landschaft. Verschiedene Ortungstechnologien verwenden beispielsweise unterschiedliche Koordinatensysteme. Positionsdaten aus GPS- und WLAN-basierenden Systemen sind nicht kombinierbar. Dies macht ein nahtloses Tracking ebenso unmöglich wie die Steuerung fahrerloser Transportsysteme.

Herausforderung

Viele Unternehmen erkennen die Potenziale einer optimierten, vielleicht sogar automatisierten Materialversorgung am Band. Solche Lösungen umzusetzen gestaltet sich heute als schwierig und der ROI ist schwer darstellbar, wodurch die Realisierung gerne mal auf die lange Bank geschoben wird. Technische Hürden und fehlende Use Cases lassen die Projekte schon in der Konzeptionsphase sterben.

Unser Beitrag

bridgingIT ist federführend an der Entwicklung der omlox-gestützten Real-Time-Location-Services-Plattform beteiligt. Durch unsere Lean-Kompetenz werden im Zuge der Einführung von Routing- und Navigationslösungen zunächst Logistik-Konzepte optimiert. Als intelligente Middleware verbindet die RTLS-Plattform dann die Ortungs- und Navigationsdaten bei drastisch reduziertem Integrationsaufwand mit der vorhandenen Business-Logik. Das Ergebnis sind transparente, messbare und automatisierbare Logistikprozesse.

Ist-Situation

Durch die Entwicklungen der letzten Jahre, die mit dem Zukauf von zusätzlichen Fertigungskapazitäten, dem Erwerb neuer Unternehmensteile und der Ansammlung vielfältiger Daten und Informationen aus dem Produktionsumfeld einher gingen, sind mittlerweile heterogene Infrastrukturen, Produktionswelten und Prozesse entstanden. Sie alle sind mit zahlreichen Herausforderungen verbunden, die ein enormes Verbesserungspotenzial in sich tragen.

Problem

Die Ausstattung von Produktionshallen und die Anordnung der Maschinen/Anlagen ist oft über Jahre gewachsen und nicht mehr optimal, wenn es um Auftragsabwicklungsprozesse, Materialtransport und Flexibilität geht. Häufig sind noch Auftragsbegleitpapiere anzutreffen, die verschwinden, verschmutzen usw. Die Folgen: eine intransparente Auftragslokalisierung und ein langsamer, ineffizienter Auftragsdurchlauf aufgrund langer Warte-, Rüst-, Wege- und Suchzeiten.

Herausforderung

Prozessoptimierungen für Shopfloor, Logistik und Administration setzen voraus, dass eine aussagekräftige Analyse der Ist-Situation existiert, geeignete Verbesserungsmaßnahmen gefunden werden und ein jederzeit nachprüfbarer Plan für eine schrittweise Umsetzung existiert. Die Messung und gezielte Beseitigung der Verschwendungspotenziale im Kontext aller Begleitprozesse ist eine große Herausforderung, die im Tagesgeschäft oft nicht geleistet werden kann.

Unser Beitrag

Lean Management ist ein wesentlicher Teil unserer Kompetenz und wir ergänzen diese Fähigkeit mit unserer IT-geprägten Umsetzungsstärke. Somit entstehen nicht nur optimierte Prozesse, sondern gleichzeitig auch die damit einhergehende IT-gestützte Infrastruktur. Die Prozessoptimierung wird mit Umsetzungskompetenz gepaart, und genau diese Brücke zum Erfolg baut bridgingIT für Sie. Alles aus einer Hand.

Ist-Situation

Klarheit und Transparenz in der Produktion, die Umsetzung einer Führungskultur, kontinuierliche Verbesserungen, Informationsaustausch und strukturierte Meetings sind Bereiche des klassischen Shopfloor-Managements. Diese Meetings werden auch für Schichtübergaben und tägliche Stand-ups zu Produktionsaufträgen genutzt. Der Aufwand für die Vorbereitung dieser Abläufe ist aufgrund vielfältiger Datenquellen und verschiedener Medien (digital und analog) nicht unerheblich.

Problem

Die Vorbereitung dieser Meetings nimmt viel Zeit in Anspruch, mit dem Ergebnis, dass die visualisierten Daten oft nicht aktuell und Ableitungen daraus nicht mehr zutreffend sind. Ausgedruckte Dokumente und händisch zusammengetragene Informationen benötigen nicht selten eine Stunde und länger. Dies beschäftigt mindestens eine Person, die damit nicht an der Wertschöpfung teilnehmen kann.

Herausforderung

Beim digitalen Shopfloor-Management sind alle KPIs und Informationen aus Drittapplikationen sowie produktionsrelevante Live-Daten auf Knopfdruck verfügbar. Wichtig sind hier die Analyse der Informationsbereitstellung und die Datenaufbereitung in aussagekräftigen Dashboards. Die großen Herausforderungen sind das UI/UX-Design, das Wann?, Wo? und Wie? der Datenvisualisierung und die Frage, welche Insights in den Verbesserungsprozess münden sollen.

Unser Beitrag

Das Vorgehensmodell der bridgingIT-Gruppe für die Einführung des digitalen Shopfloor-Managements basiert auf Microsoft 365. Dabei entsteht quasi aus „Bordmitteln“ ein MVP, mit dem Sie das Thema erkunden, weiterentwickeln und Anforderungen an eine proprietäre Softwarelösung formulieren können. Das spart Kosten, bindet alle Beteiligten in das Projekt ein und sichert eine schnelle, erfolgreiche Prozessentfaltung.

Ist-Situation

Der After Sales Bereich ist heute in der produzierenden Industrie ein wesentlicher Teil der Wertschöpfung. Aktuell werden durchschnittlich 30% der gesamten Wertschöpfung durch Ersatzteillieferungen und Services erzielt, die nach dem Verkauf des Produkts stattfinden. Der Vorteil bei diesem Bereich der Wertschöpfung ist, dass die Umsätze relativ krisenfest und konstant sind. Sie sollten daher in Zukunft anteilig höher sein.

Problem

Die Erhöhung der Wertschöpfung im After Sales und die Etablierung neuer Geschäftsmodelle scheitert oft an der noch fehlenden Digitalisierung von Informationsflüssen, der DSGVO, der Weigerung der Kunden, Informationen offenzulegen, oder an einer passenden Infrastruktur. Serviceportale waren der erste Schritt in die richtige Richtung, haben allerdings die Umsätze nur selten signifikant erhöht.

Herausforderung

Wie muss eine leistungsfähige, digitale Infrastruktur aussehen, welchen Sicherheitsrichtlinien muss sie entsprechen und wie kann eine vertrauensvolle Zusammenarbeit mit dem Endkunden gewährleistet werden? Welche Abrechnungsmodelle und welche dazu passenden Online-Dienste können dazu beitragen, die Wertschöpfung im After Sales zu steigern? Wie können MVPs für Tests aussehen, um zu ersten Aussagen zu kommen?

Unser Beitrag

Aufgrund unserer Rolle als Inkubator und Accelerator für Start-ups besitzen wir ausreichende Kompetenz, um neue Geschäftsmodelle auch für den After-Sales-Bereich zu entwickeln. Hinzu kommen Kompetenzen und Umsetzungs-Know-how für IT-Infrastrukturen und IT-Architekturen, gepaart mit der Einhaltung der DSGVO. Somit liefern wir Ideen und ihre Realisierung sowie Governance, Compliance und Risk Assessment aus einer Hand.

Ist-Situation

Die Kundenanforderungen werden immer komplexer und vielschichtiger. Die Sales-Organisation steht dadurch vor einer Herausforderung: Sie muss Informationen zu diesen sich wandelnden Anforderungen schnell, fehlerfrei und eindeutig an die Konstruktion, Arbeitsvorbereitung und Produktion übergeben. Diese Informationen werden sowohl für die Angebotskalkulation und die Vorbereitung der Fertigung als auch für den gesamten PLM/PDM-Prozess benötigt.

Problem

Viele Informationen, die über die Sales-Organisation in die Unternehmen gelangen, existieren als schnelle Mitschriften auf Papier. Dies ist oft schon die erste Fehlerquelle und führt zu langwierigen Nachfragen beim Kunden und höheren Aufwänden bei der Angebotserstellung. Hinzu kommen sehr oft erhebliche Anstrengungen der Unternehmen, neue Märkte/Regionen zu erschließen, weil immer noch die klassische Vertriebsniederlassung dominiert.

Herausforderung

Wie helfe ich meinem Kunden, seine Produktanforderungen digital, eindeutig und fehlerfrei an potenzielle Lieferanten zu übergeben, um schnell ein verlässliches Angebot zu bekommen?

Im Auftragsfall müssen die vorhandenen Informationen für Auftragsdurchlauf/PLM/PDM und After Sales mitgenutzt werden können. Zudem müssen Social-Media-Plattformen und CRM für die globale Neukundengewinnung (auch ohne lokales Vertriebsbüro) verknüpft werden.

Unser Beitrag

Online-Produktkonfiguratoren, Augmented und Virtual Reality unterstützen die Optimierung der Vertriebsprozesse. Unsere diesbezügliche Beratungs- und Umsetzungskompetenz haben wir in Projekten mehrfach bewiesen. Dies gilt auch für den Bereich des Online-Marketings und der Remote-Sales-Prozesse sowie deren Anbindung an CRM-Systeme. Ziel ist es immer, ohne Medienbrüche genügend Informationen vom Markt zu erhalten und effektive Vertriebsprozesse aufzusetzen.

Ausgewählte Referenzen

Mit unserer Branchen- und Technologieexpertise gelingt es uns, den Anforderungen unserer Manufacturing-Kunden flexibel und individuell gerecht zu werden. In unterschiedlichen Anwendungsfällen konnten wir nachhaltige Geschäftsmodelle und mehrwertstiftende, digitale Services entwickeln. Unsere Referenzen geben Ihnen ein Bild von unserer Arbeit.

Ausgewählte Referenzen

Mit unserer Branchen- und Technologieexpertise gelingt es uns, den Anforderungen unserer Manufacturing-Kunden flexibel und individuell gerecht zu werden. In unterschiedlichen Anwendungsfällen konnten wir nachhaltige Geschäftsmodelle und mehrwertstiftende, digitale Services entwickeln. Unsere Referenzen geben Ihnen ein Bild von unserer Arbeit.

Ausgewählte Referenzen

Mit unserer Branchen- und Technologieexpertise gelingt es uns, den Anforderungen unserer Manufacturing-Kunden flexibel und individuell gerecht zu werden. In unterschiedlichen Anwendungsfällen konnten wir nachhaltige Geschäftsmodelle und mehrwertstiftende, digitale Services entwickeln. Unsere Referenzen geben Ihnen ein Bild von unserer Arbeit.

Transparent, kalkulierbar und nachhaltig

Mit intelligenten Industrie 4.0 Logistiksystemen lassen sich Prozessabläufe detailliert analysieren. Prozesse, die für Verschwendung und Zeitverlust sorgen, können so identifiziert und optimiert werden.Transparent, kalkulierbar und nachhaltig

Mit intelligenten Industrie 4.0 Logistiksystemen lassen sich Prozessabläufe detailliert analysieren. Prozesse, die für Verschwendung und Zeitverlust sorgen, können so identifiziert und optimiert werden.Transparent, kalkulierbar und nachhaltig

Mit intelligenten Industrie 4.0 Logistiksystemen lassen sich Prozessabläufe detailliert analysieren. Prozesse, die für Verschwendung und Zeitverlust sorgen, können so identifiziert und optimiert werden.Unsere wertschöpfenden Leistungen für Manufacturer

Unsere wertschöpfenden Leistungen für Manufacturer

Unsere wertschöpfenden Leistungen für Manufacturer

Technologien

Für die Umsetzung der digitalen Transformation setzen wir auf leistungsfähige Technologien und Partnerschaften, die sich im Markt bewährt haben. Wir beraten Sie bei Fragen zu Technologien, Industriestandards und digitalen Lösungswegen im Manufacturing-Umfeld.

Technologien

Für die Umsetzung der digitalen Transformation setzen wir auf leistungsfähige Technologien und Partnerschaften, die sich im Markt bewährt haben. Wir beraten Sie bei Fragen zu Technologien, Industriestandards und digitalen Lösungswegen im Manufacturing-Umfeld.

Technologien

Für die Umsetzung der digitalen Transformation setzen wir auf leistungsfähige Technologien und Partnerschaften, die sich im Markt bewährt haben. Wir beraten Sie bei Fragen zu Technologien, Industriestandards und digitalen Lösungswegen im Manufacturing-Umfeld.

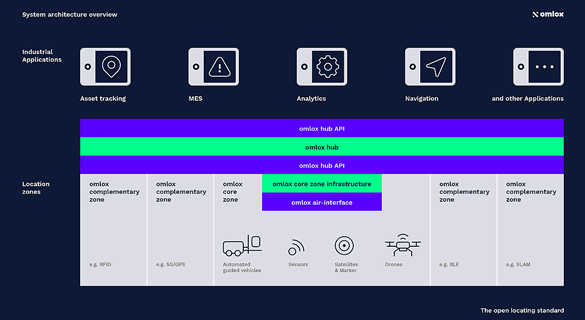

omlox

Der Standard für Ortungstechnologien

Der neue Industriestandard omlox ermöglicht es, alle vorhandenen Technologien wie UWB, BLE, RFID, 5G oder GPS zu verknüpfen, und stellt die Ortungsdaten über eine einheitliche Schnittstelle bereit. Dies ermöglicht eine vernetzte Logistik und eine effiziente Fertigung.

Gemeinsam mit unseren über 60 Partnern helfen wir Ihnen, Ihre Herausforderungen zu meistern.

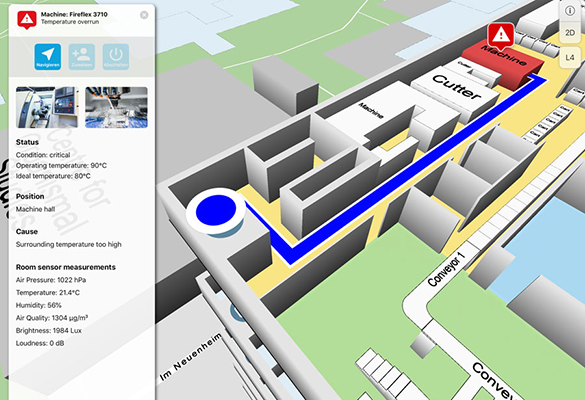

Deep Map™

Mit fundierten Geoanalysen nutzen Sie Ihre vernetzten, ortsbezogenen Daten gewinnbringend. Die Deep Map™ Technologie visualisiert werksinterne Bewegungsmuster von Gütern, Personen und Hilfsmitteln. Performanz, Potenziale und Probleme werden in Echtzeit oder retrospektiv offengelegt, damit Sie Prozesse zeitnah optimieren können.

Xetics™

Mit Xetics™ Lean können wir Ihnen eine cloudbasierte IT-Applikation anbieten, welche die Prozessoptimierung, egal ob im Shopfloor oder in der Administration, nachhaltig unterstützt.

Mit dem Lean-Ansatz favorisieren wir schlanke Abläufe und ebnen den Weg in die Smart Factory.

Partner

Partner

Partner

Ihr Kontakt zu uns

Bei allen Fragen zur digitalen Transformation in der Fertigungs- und Prozessindustrie beraten Sie unsere erfahrenen Kollegen.

Ihr Kontakt zu uns

Bei allen Fragen zur digitalen Transformation in der Fertigungs- und Prozessindustrie beraten Sie unsere erfahrenen Kollegen.

Ihr Kontakt zu uns

Bei allen Fragen zur digitalen Transformation in der Fertigungs- und Prozessindustrie beraten Sie unsere erfahrenen Kollegen.

Kontaktformular

Sie haben Fragen oder Anregungen? Wir freuen uns auf Ihre Anfrage.

Kontaktformular

Sie haben Fragen oder Anregungen? Wir freuen uns auf Ihre Anfrage.

Kontaktformular

Sie haben Fragen oder Anregungen? Wir freuen uns auf Ihre Anfrage.